MS3

Chamber for interface slice preparations on a compound microscope

- Overview

- Specifications

- Accessories

- Citations

- Related Products

Overview

There are 1 images available to view - click to enlarge and scroll through the product gallery.

MS3 Brochure

/ Download as PDF

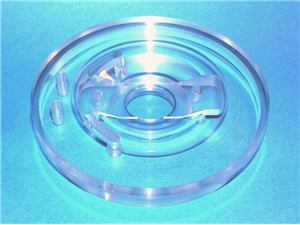

The MS3 chamber design is based on our BSC2 chamber and allows interface methods of slice maintenance on a compound microscope stage. Experiments can be performed either at room temperature or at a pre-determined temperature with the addition of our in-line solution heater MH02 system.

- Slices supported in removable template

- Removable templates for ease of cleaning and maintenance

- Coverslip base allows for high quality imaging with normal condenser optics.

- Template design with diamond shaped flow cell for perfusion of slices with a small dead-space.

- Temperature control system available

- Custom designed templates available.

The MS3 chamber is constructed from clear acrylic having a diameter of 100mm, height is 20mm. It is normally arranged on the microscope stage with an adaptor plate to allow the optical base of the chamber to be in close proximity to the microscope condenser optics for optimal visualisation. The slices rest in flat channel which has a central coverslip base 20mm in diameter. By placing various types of templates which have an inlet and exit well for perfusion solution, fluid flows in a narrow diamond shaped channel above the coverslip base whilst a high oxygen tension is maintained above it. The slices normally rest on a piece of lens tissue while being perfused from one end of the insert. Perfusion solution height is adjusted at the exit well to maintain interface mode.This is done by arranging lens tissue to wick solution into the exit well where it is removed by a tube attached to a suction line / peristaltic pump system. The pre-moistened carbogen gas enters from two inlets at the bottom of the chamber and is then deflected by a profiled acrylic lid on to the surface of the interface slice preparation resting in the central area of the glass coverslip. At the exit well perfusion solution can be collected for re-circulation or analysis. The half circle profiled acrylic lid allows access for stimulating and recording electrodes. Provision is made for a reference electrode wire to enter the proximity of the insert. The chamber can be set up for temperature controlled perfusion solution with the in-line heater system MH02 is used in conjunction with the proportional temperature controller PTC03. A further requirement for temperature control is that the pre-moistened gas is supplied from a gas wash bottle immersed in a standard laboratory heated water bath to increase the input temperature and humidity levels.

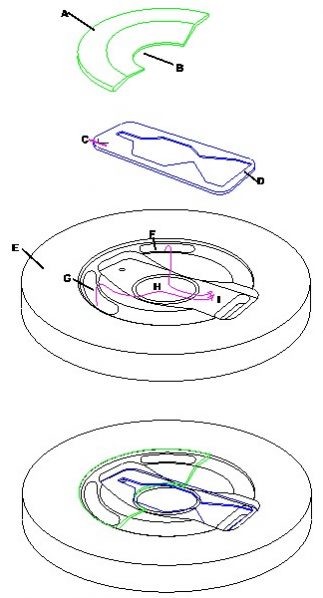

Schematic

An exploded view of the chamber components to show assembly

Parts description

Deflector lid [A] with cut out [B] in lid for access to slices. Template[C] Exit for perfusion solution [D]. Main body of MS3 chamber [E] Port holes for entry of humidified carbogen gas mixture[F] & [G]. Glass coverslip base [H] and resting place for slices where humidified carbogen gas is directed by lid [A] in direction shown by arrows [I]

Request

Catalogue

Chat

Print