ez-gSEAL 100B Pressure Controller

Make the perfect seals for your patch-clamp recordings!

- Overview

- Specifications

- Accessories

- Citations

- Related Products

Overview

The ez-gSEAL 100B pressure controller is primarily designed for automated patch clamping, but its versatility allows for various other applications.

With a simple click of a button, the ez-gSEAL pressure controller makes patch clamping effortless. It can be used in conjunction with motorised manipulators and patch clamp systems. Alternatively, it can be used as a stand-alone product on a traditional rig. Moreover, the controller can be utilized for drug puffing or studying stretch channels. The software-controlled pressure controller comes equipped with pumps, thereby eliminating the need for air tanks.

Advantages

Compared to traditional methods of making seals, there are many advantages in using the ez-gSEAL pressure controller:

- You can set a very small holding pressure during experiments so that the seals last a long time.

- Patch clamp experiments become precise and reproducible. Using a syringe or mouth suction to break into cells can make it difficult to control the pressure, resulting in inconsistent and unreliable results. However, with the ez-gSEAL pressure controller, you can define the suction pressure and duration for break-in, leading to consistent and reliable results. It is also rare for the membrane to reseal after breaking in with the ez-gSEAL pressure controller, but if it does happen, you can easily apply more suction without touching the rig.

- It is easy and stress free. Instead of tensely controlling the pressure yourself, you only need to click a few buttons for making seals and breaking in. This takes away the stress from you so that you can be more productive in a day.

- Training time is shorter. So far, even students with little experience in patch clamping can make seals with our parameters.

- It is easy for trouble-shooting. When the success rate of making seals suddenly becomes low, you will not need to spend endless efforts trying to improve your seal skills, but instead focus on the possible real reasons such as cell conditions, solutions or patch pipettes.

- The skill is good forever. Most patch clampers experienced that after you stop doing experiments for a while, you lose your skills. With the ez-gSEAL, you can easily reach your normal seal success rate as long as you record your seal parameters.

- High success rate. The success rate to make seals and break in is at least as good as traditional methods, if not better.

The ez-gSEAL 100B pressure controller boasts several enhancements compared to its predecessor, the 100A model. The pumps are now more robust and have an extended lifespan. Furthermore, the air flow within the unit has been optimized, leading to superior performance. Additionally, the unit now includes a pressure gauge that assists users in determining the ideal pressure for making seals and breaking in.

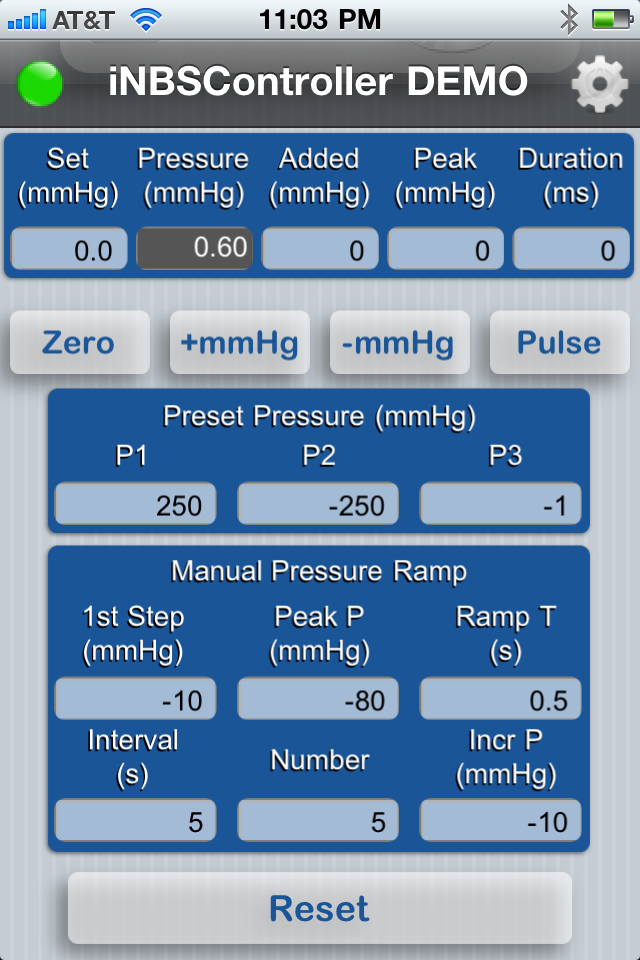

Software Control

The NBSController, which is the ez-gSEAL control software, regulates pressure application and measures pressure. It conveniently enables users to preset commonly-used pressures, simplifying the process of making seals and breaking in. With just a few clicks, users can achieve their desired outcomes.

.jpg)

Ios Touch Control

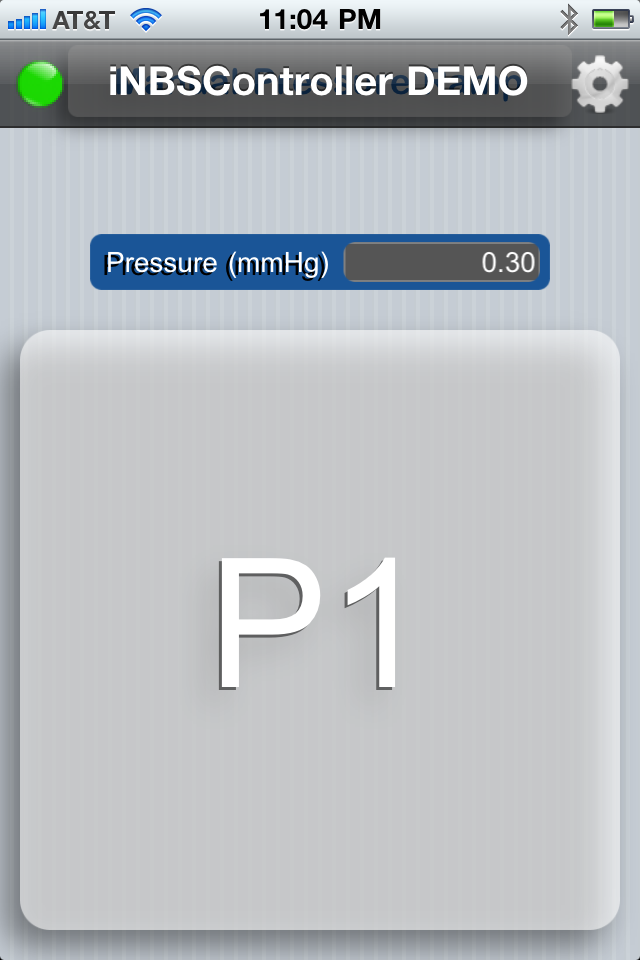

The ez-gSEAL pressure controller is compatible with iPhone, iPad or iPod Touch. By connecting to the server software, the NBSController, through WiFi, users can utilize their Ios device as a remote control to operate the device from their setup. This feature provides users with the flexibility to control the pressure controller at a distance.

Similar to the NBSController, the iNBSController is designed with ease-of-use in mind, allowing users to modify values quickly. Additionally, the iNBSController plays pre-saved parameters for making seals and breaking in sequentially, enabling users to select the appropriate button without the need to look at the device. This feature is especially valuable when users have to adjust focus with one hand and control a manipulator with the other while simultaneously generating suction to make a seal. By having the iPod Touch or iPhone within close reach, users can use a single finger or elbow to activate the pulse via the touch screen.

Key Functions

Patch Clamp

With the ez-gSEAL pressure controller, patch clamping experiments become remarkably simple, requiring only a few clicks of a button. To initiate the process, users click the first button to set the positive pressure, followed by the second button to set the negative pressure required for making seals, and the third button to set the holding pressure. Breaking into the cell is equally straightforward, requiring users to click a single button to apply pulses. Thanks to its intuitive design, the ez-gSEAL pressure controller streamlines complicated patch clamp experiments, making them significantly easier to perform.

The measurement function of the ez-gSEAL control software enables users to accurately measure the pressure required for making seals and breaking in. Additionally, a wide range of cells and tissues, including HEK293 cells, brain slices, and oocytes, have been tested, and the seal parameters are readily available for these types of samples. New users can conveniently leverage these parameters to make seals and break in during their first attempt. To obtain available seal parameters, please contact NeoBiosystems.

With the incorporation of a DAQ board from National Instruments and our BNC interface box, the process of making seals and breaking in can be completed with just a single click of a button. This streamlined approach significantly simplifies the entire process, allowing researchers to perform their experiments with ease and accuracy.

When used in conjunction with the ezPATCH 100A manipulator, patch clamping becomes even simpler. All that is required is to aim the patch pipette at the cell that requires patching. Once the button is clicked, the pipette will touch the cell, creating a seal or even achieving whole-cell configuration automatically. This intuitive approach minimizes user error and streamlines the patch clamping process for optimal efficiency.

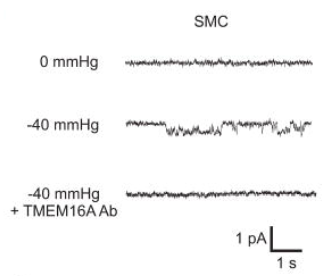

Pressure control for stretch channel study

In addition to patch clamping, the ez-gSEAL pressure controller can also be used for pressure clamping in the study of stretch channels. With a high pressure sensitivity of 1.5 mmHg and an expansive pressure range from -250 mmHg to 250 mmHg, it is capable of handling most stretch channels. This makes it an ideal tool for researchers studying this field.

Bulley S, Neeb ZP, Burris SK, Bannister JP, Thomas-Gatewood CM, Jangsangthong W, Jaggar JH. (2012) TMEM16A/ANO1 Channels Contribute to the Myogenic Response in Cerebral Arteries. Circ Res. 111(8):1027-36.

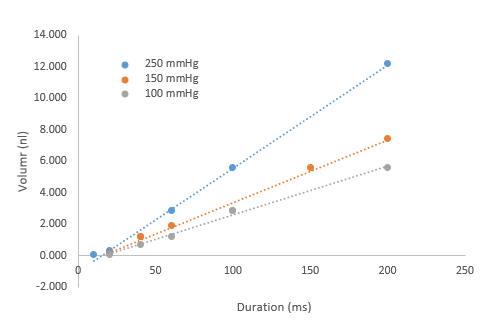

Pressure control for drug application

Beyond patch clamping and stretch channel studies, the ez-gSEAL pressure controller is also useful for local drug application. By delivering a series of pressure pulses at defined pressures for defined durations, it can accurately and precisely administer drugs to specific locations. This functionality can greatly enhance the precision and efficiency of drug studies, making the ez-gSEAL pressure controller a valuable tool for researchers in pharmacology and related fields.

Data from research labs

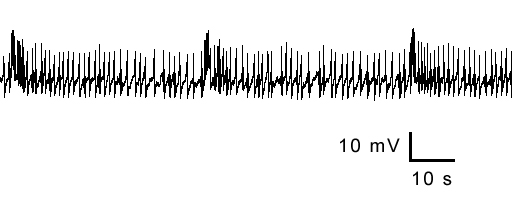

Figure 1 Recording obtained at the Marine Biological Laboratory using the ez-gSEAL 100A pressure controller. LNV clock neurons in female Drosophila were used for electrophysiological recordings. A 6-7 micrometer diameter pipette filled with protease XIV was first used to digest the tissue above the clock neurons. The pressure setting for applying the protease XIV was 20 - 30 mmHg. When making the seal, 40 mmHg pressure was applied during the time the patch pipette (polished. Resistance ~ 17 MOhms) approached the neuron, and then -20 mmHg suction was applied to make the seal. The breaking-in pressure for this cell was -200 to -250 mmHg for 0.5 s. The holding pressure was -1 mmHg to keep the seal stable during the recording. This recording was obtained 3.5 hours after making the seal, and the cell was still healthy.

Faculties: Dr. Guan Cao, University of Texas; Dr. Michael Nitaback, Yale University.

Reference: Guan Cao and Michael N. Nitabach (2008) J. Neurosci., 28(25):6493-6501

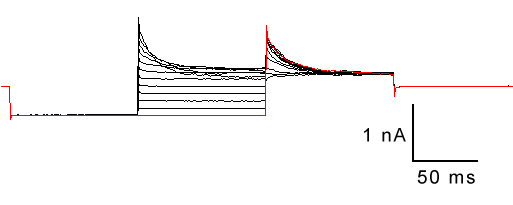

Figure 2 Suspension of HEK cells expressing ClC-0/C212S chloride channels. When making the seal, 5 mmHg pressure was applied during the time the patch pipette (Resistance ~ 2 MOhms) approached the cell, and then -40 mmHg suction was applied to make the seal.

Obtained from Dr. Xiaodong Zhang and Dr. Tsung-Yu Chen, University of California, Davis.

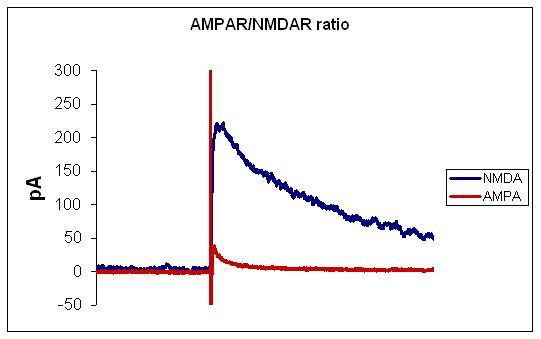

Figure 3 Sample AMPAR-and NMDAR-mediated current recorded from VTA DA neuron of p80 and older mouse. When making the seal, 50 mmHg pressure was applied during the time the patch pipette (Resistance ~ 2 MOhms) approached the neuron, and then -20 to -40 mmHg suction was applied to make the seal. The breaking-in pressure for this cell was -150 for 0.5 s.

Obtained from Dr. Billy Chen, Ernest Gallo Clinic and Research Center, UCSF.

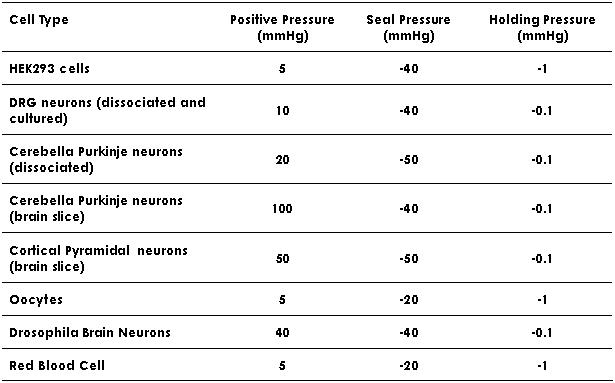

Making Seal Parameters

Please refer to the tables below for the making seal and breaking in parameters when using the ez-gSEAL 100B Pressure Controller. Based on our experience, these parameters should enable most labs to make seals with ease. However, please note that the required break-in pressure may vary somewhat depending on the size of the patch pipette tip. As a general rule, larger openings require smaller break-in pressures.

Table 1 Making seal parameters for different cell types.

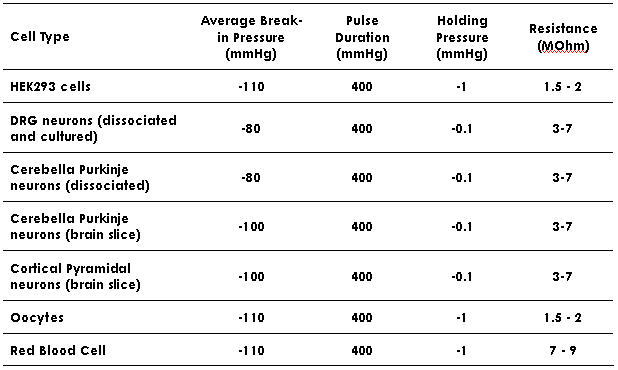

Table 2 Break-in parameters for different cell types. Since the required break-in pressure is depended on the tip size of the patch pipette, the resistances of the pipettes are included.

Computer Requirements

- Windows 7, 8, or 10 with 2.0 GHz CPU and up

- 1 USB port

Specifications

Pressure range: -250 mmHg to 250 mmHg

Pressure resolution: +/- 1.5 mmHg

Minimal pulse duration: 7 ms

Minimal pulse interval: 7 ms

Maximum flow rate: 33 sclm

Filtration: 40 micron

Computer interface: USB*

Line voltage: 110 VAC to 240 VAC

Dimension: 17" x 14" x 3.5" rack mount or desk top

Weight: 5 Kg

*Computer Requirements: Windows 7, 8, 10 or 11 with 2.0 GHz CPU and up with a USB port

Request

Catalogue

Chat

Print