Setting Up SmartFlo When Using A Flow Sensor

SmartFlo: Common commands for ExiGo Syringe Pumps, UniGo and 4U Pressure Pumps

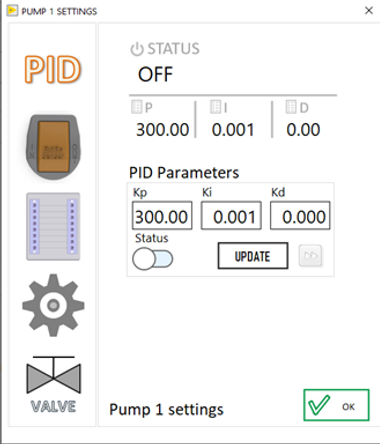

SmartFlo is the software program used to program ExiGo syringe pumps and Unigo & 4U pressure pumps. You can use SmartFlo to control the PID settings for your microfluidic pump.

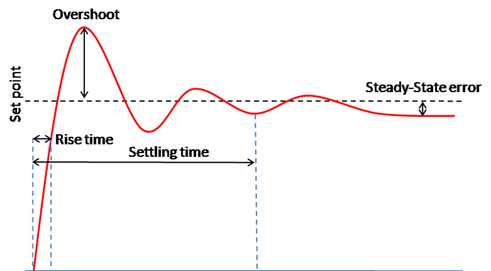

Proportional (Kp)

The proportional gain defines how quickly the system will change its output to reduce the existing error (Flow rate set point minus current flow rate). Therefore, the proportional parameter will increase the speed of the control system response. However, if the proportional value is too large, the system will begin to oscillate. Using P parameter on its own may lead to a Steady-State error (offset) between desired flow rate and current flow rate.

Integral (Ki)

The integral term sums the instantaneous flow rate error over time and gives the accumulated offset that should have been corrected. Thus, its main purpose is to drive the flow rate Steady-State error to zero. A large value of the Integral parameter may cause the system to overshoot the set point value and even oscillate.

Derivative (Kd)

The derivative term is proportional to the rate of change of the system output (pump flow rate). Therefore it “predicts” the system behaviour decreasing the system output if the flow rate is changing rapidly. This parameter helps to reduce overshoot and settling time but an incorrect value may cause the system to become unstable.

How to tune the PID settings

1. Set all parameters to 0.

2. Increase P and change the set point until the dynamic response of the pump is fast enough without oscillating.

3. Increase gradually I value in order to minimize the Steady-State error. Integral parameter can be any value between 0 and 1 but it is very sensitive and may cause the system to oscillate. Therefore it is recommended to start using a value of 0.001. A value over 0.1 will probably lead the system to become unstable.

4. In case of a large overshoot when changing the set point, increase the D value gradually until the optimal ratio overshoot/response time is achieved. However, a large value of D may slow down the dynamic response of the system.

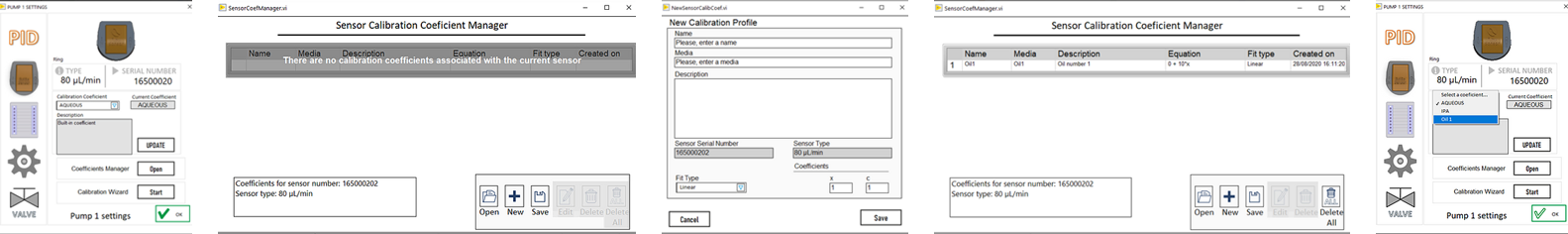

Flow Sensor Coefficients

These flow sensors are calibrated for aqueous solutions by default. Running other liquids such as oils, IPAs etc, through the sensor using the default coefficient would result in an incorrect flow rate reading. However it is possible to add a custom calibration coefficient to correct the reading.[1]

Warning: Introducing the wrong coefficient might lead to an incorrect flow measurement and cause damage to your pump and/or your setup. Please, contact Cellix for more information on how to use custom calibration coefficients.

Request

Catalogue

Chat

Print