- Page 1

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Page 65

- Page 66

- Page 67

- Page 68

- Page 69

- Page 70

- Page 71

- Page 72

- Page 73

- Page 74

- Page 75

- Page 76

- Page 77

- Page 78

- Page 79

- Page 80

- Page 81

- Page 82

- Page 83

- Page 84

- Page 85

- Page 86

- Page 87

- Page 88

- Page 89

- Page 90

- Page 91

- Page 92

- Page 93

- Page 94

- Page 95

- Page 96

- Page 97

- Page 98

- Page 99

- Page 100

- Page 101

- Page 102

- Page 103

- Page 104

- Page 105

- Page 106

- Page 107

- Page 108

- Page 109

- Page 110

- Page 111

- Page 112

- Page 113

- Page 114

- Page 115

- Page 116

- Page 117

- Page 118

- Page 119

- Page 120

- Page 121

- Page 122

- Page 123

- Page 124

- Page 125

- Page 126

- Page 127

- Page 128

- Page 129

- Page 130

- Page 131

- Page 132

- Page 133

- Page 134

- Page 135

- Page 136

- Page 137

- Page 138

- Page 139

- Page 140

- Page 141

- Page 142

- Page 143

- Page 144

- Page 145

- Page 146

- Page 147

- Page 148

- Page 149

- Page 150

- Page 151

- Page 152

- Page 153

- Page 154

- Page 155

- Page 156

- Page 157

- Page 158

- Page 159

- Page 160

- Page 161

- Page 162

- Page 163

- Page 164

- Page 165

- Page 166

- Page 167

- Page 168

- Page 169

- Page 170

- Page 171

- Page 172

- Page 173

- Page 174

- Page 175

- Page 176

- Page 177

- Page 178

- Page 179

- Page 180

- Page 181

- Page 182

- Page 183

- Page 184

- Page 185

- Page 186

- Page 187

- Page 188

- Page 189

- Page 190

- Page 191

- Page 192

- Page 193

- Page 194

- Page 195

- Page 196

- Page 197

- Page 198

- Page 199

- Page 200

- Page 201

- Page 202

- Page 203

- Page 204

- Page 205

- Page 206

- Page 207

- Page 208

- Page 209

- Page 210

- Page 211

- Page 212

- Flash version

© UniFlip.com

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Page 65

- Page 66

- Page 67

- Page 68

- Page 69

- Page 70

- Page 71

- Page 72

- Page 73

- Page 74

- Page 75

- Page 76

- Page 77

- Page 78

- Page 79

- Page 80

- Page 81

- Page 82

- Page 83

- Page 84

- Page 85

- Page 86

- Page 87

- Page 88

- Page 89

- Page 90

- Page 91

- Page 92

- Page 93

- Page 94

- Page 95

- Page 96

- Page 97

- Page 98

- Page 99

- Page 100

- Page 101

- Page 102

- Page 103

- Page 104

- Page 105

- Page 106

- Page 107

- Page 108

- Page 109

- Page 110

- Page 111

- Page 112

- Page 113

- Page 114

- Page 115

- Page 116

- Page 117

- Page 118

- Page 119

- Page 120

- Page 121

- Page 122

- Page 123

- Page 124

- Page 125

- Page 126

- Page 127

- Page 128

- Page 129

- Page 130

- Page 131

- Page 132

- Page 133

- Page 134

- Page 135

- Page 136

- Page 137

- Page 138

- Page 139

- Page 140

- Page 141

- Page 142

- Page 143

- Page 144

- Page 145

- Page 146

- Page 147

- Page 148

- Page 149

- Page 150

- Page 151

- Page 152

- Page 153

- Page 154

- Page 155

- Page 156

- Page 157

- Page 158

- Page 159

- Page 160

- Page 161

- Page 162

- Page 163

- Page 164

- Page 165

- Page 166

- Page 167

- Page 168

- Page 169

- Page 170

- Page 171

- Page 172

- Page 173

- Page 174

- Page 175

- Page 176

- Page 177

- Page 178

- Page 179

- Page 180

- Page 181

- Page 182

- Page 183

- Page 184

- Page 185

- Page 186

- Page 187

- Page 188

- Page 189

- Page 190

- Page 191

- Page 192

- Page 193

- Page 194

- Page 195

- Page 196

- Page 197

- Page 198

- Page 199

- Page 200

- Page 201

- Page 202

- Page 203

- Page 204

- Page 205

- Page 206

- Page 207

- Page 208

- Page 209

- Page 210

- Page 211

- Page 212

- Flash version

© UniFlip.com

Patch Clamp Capillary Glass

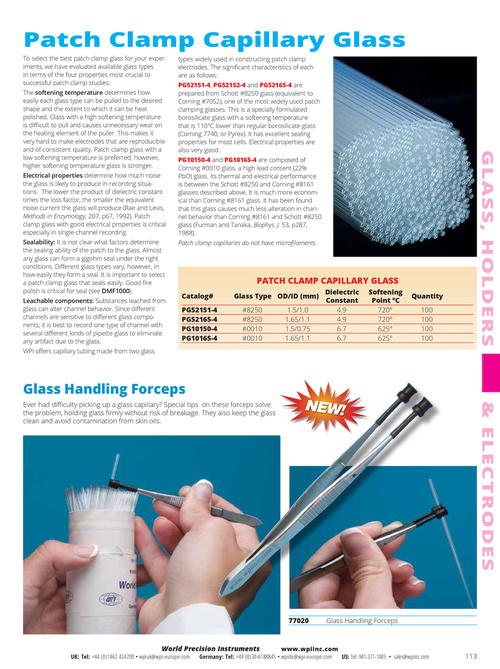

To select the best patch clamp glass for your experiments, we have evaluated available glass types in terms of the four properties most crucial to successful patch clamp studies: The softening temperature determines how easily each glass type can be pulled to the desired shape and the extent to which it can be heat polished. Glass with a high softening temperature is difficult to pull and causes unnecessary wear on the heating element of the puller. This makes it very hard to make electrodes that are reproducible and of consistent quality. Patch clamp glass with a low softening temperature is preferred; however, higher softening temperature glass is stronger. Electrical properties determine how much noise the glass is likely to produce in recording situations. The lower the product of dielectric constant times the loss factor, the smaller the equivalent noise current the glass will produce (Rae and Levis, Methods in Enzymology, 207, p67, 1992). Patch clamp glass with good electrical properties is critical especially in single-channel recording. Sealability: It is not clear what factors determine the sealing ability of the patch to the glass. Almost any glass can form a gigohm seal under the right conditions. Different glass types vary, however, in how easily they form a seal. It is important to select a patch clamp glass that seals easily. Good fire polish is critical for seal (see DMF1000). Leachable components: Substances leached from glass can alter channel behavior. Since different channels are sensitive to different glass components, it is best to record one type of channel with several different kinds of pipette glass to eliminate any artifact due to the glass. WPI offers capillary tubing made from two glass types widely used in constructing patch clamp electrodes. The significant characteristics of each are as follows: PG52151-4, PG52152-4 and PG52165-4 are prepared from Schott #8250 glass (equivalent to Corning #7052), one of the most widely used patch clamping glasses. This is a specially formulated borosilicate glass with a softening temperature that is 110°C lower than regular borosilicate glass (Corning 7740, or Pyrex). It has excellent sealing properties for most cells. Electrical properties are also very good. PG10150-4 and PG10165-4 are composed of Corning #0010 glass, a high lead content (22% PbO) glass. Its thermal and electrical performance is between the Schott #8250 and Corning #8161 glasses described above. It is much more economical than Corning #8161 glass. It has been found that this glass causes much less alteration in channel behavior than Corning #8161 and Schott #8250 glass (Furman and Tanaka, Biophys. J. 53, p287, 1988). Patch clamp capillaries do not have microfilaments.

GLASS, HOLDERS

PATCH CLAMP CAPILLARY GLASS

Catalog# PG52151-4 PG52165-4 PG10150-4 PG10165-4 Glass Type OD/ID (mm) #8250 #8250 #0010 #0010 1.5/1.0 1.65/1.1 1.5/0.75 1.65/1.1 Dielectric Constant 4.9 4.9 6.7 6.7 Softening Point °C 720° 720° 625° 625° Quantity 100 100 100 100

Glass Handling Forceps

Ever had difficulty picking up a glass capillary? Special tips on these forceps solve the problem, holding glass firmly without risk of breakage. They also keep the glass clean and avoid contamination from skin oils.

& ELECTRODES

77020

Glass Handling Forceps

UK: Tel: +44 (0)1462 424700 • wpiuk@wpi-europe.com

World Precision Instruments

www.wpiinc.com Germany: Tel: +49 (0)30-6188845 • wpide@wpi-europe.com US: Tel: 941-371-1003 • sales@wpiinc.com

113