- Page 1

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Page 65

- Page 66

- Page 67

- Page 68

- Page 69

- Page 70

- Page 71

- Page 72

- Page 73

- Page 74

- Page 75

- Page 76

- Page 77

- Page 78

- Page 79

- Page 80

- Page 81

- Page 82

- Page 83

- Page 84

- Page 85

- Page 86

- Page 87

- Page 88

- Page 89

- Page 90

- Page 91

- Page 92

- Page 93

- Page 94

- Page 95

- Page 96

- Page 97

- Page 98

- Page 99

- Page 100

- Page 101

- Page 102

- Page 103

- Page 104

- Page 105

- Page 106

- Page 107

- Page 108

- Page 109

- Page 110

- Page 111

- Page 112

- Page 113

- Page 114

- Page 115

- Page 116

- Page 117

- Page 118

- Page 119

- Page 120

- Page 121

- Page 122

- Page 123

- Page 124

- Page 125

- Page 126

- Page 127

- Page 128

- Page 129

- Page 130

- Page 131

- Page 132

- Page 133

- Page 134

- Page 135

- Page 136

- Page 137

- Page 138

- Page 139

- Page 140

- Page 141

- Page 142

- Page 143

- Page 144

- Page 145

- Page 146

- Page 147

- Page 148

- Page 149

- Page 150

- Page 151

- Page 152

- Page 153

- Page 154

- Page 155

- Page 156

- Page 157

- Page 158

- Page 159

- Page 160

- Page 161

- Page 162

- Page 163

- Page 164

- Page 165

- Page 166

- Page 167

- Page 168

- Page 169

- Page 170

- Page 171

- Page 172

- Page 173

- Page 174

- Page 175

- Page 176

- Page 177

- Page 178

- Page 179

- Page 180

- Page 181

- Page 182

- Page 183

- Page 184

- Page 185

- Page 186

- Page 187

- Page 188

- Page 189

- Page 190

- Page 191

- Page 192

- Page 193

- Page 194

- Page 195

- Page 196

- Page 197

- Page 198

- Page 199

- Page 200

- Page 201

- Page 202

- Page 203

- Page 204

- Page 205

- Page 206

- Page 207

- Page 208

- Page 209

- Page 210

- Page 211

- Page 212

- Flash version

© UniFlip.com

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Page 65

- Page 66

- Page 67

- Page 68

- Page 69

- Page 70

- Page 71

- Page 72

- Page 73

- Page 74

- Page 75

- Page 76

- Page 77

- Page 78

- Page 79

- Page 80

- Page 81

- Page 82

- Page 83

- Page 84

- Page 85

- Page 86

- Page 87

- Page 88

- Page 89

- Page 90

- Page 91

- Page 92

- Page 93

- Page 94

- Page 95

- Page 96

- Page 97

- Page 98

- Page 99

- Page 100

- Page 101

- Page 102

- Page 103

- Page 104

- Page 105

- Page 106

- Page 107

- Page 108

- Page 109

- Page 110

- Page 111

- Page 112

- Page 113

- Page 114

- Page 115

- Page 116

- Page 117

- Page 118

- Page 119

- Page 120

- Page 121

- Page 122

- Page 123

- Page 124

- Page 125

- Page 126

- Page 127

- Page 128

- Page 129

- Page 130

- Page 131

- Page 132

- Page 133

- Page 134

- Page 135

- Page 136

- Page 137

- Page 138

- Page 139

- Page 140

- Page 141

- Page 142

- Page 143

- Page 144

- Page 145

- Page 146

- Page 147

- Page 148

- Page 149

- Page 150

- Page 151

- Page 152

- Page 153

- Page 154

- Page 155

- Page 156

- Page 157

- Page 158

- Page 159

- Page 160

- Page 161

- Page 162

- Page 163

- Page 164

- Page 165

- Page 166

- Page 167

- Page 168

- Page 169

- Page 170

- Page 171

- Page 172

- Page 173

- Page 174

- Page 175

- Page 176

- Page 177

- Page 178

- Page 179

- Page 180

- Page 181

- Page 182

- Page 183

- Page 184

- Page 185

- Page 186

- Page 187

- Page 188

- Page 189

- Page 190

- Page 191

- Page 192

- Page 193

- Page 194

- Page 195

- Page 196

- Page 197

- Page 198

- Page 199

- Page 200

- Page 201

- Page 202

- Page 203

- Page 204

- Page 205

- Page 206

- Page 207

- Page 208

- Page 209

- Page 210

- Page 211

- Page 212

- Flash version

© UniFlip.com

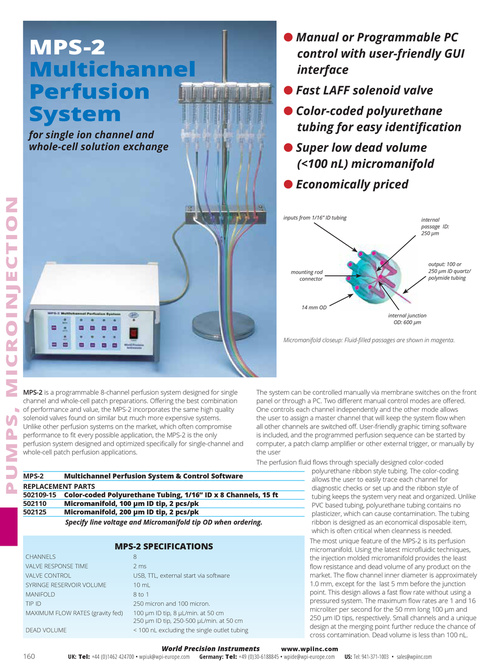

MPS-2 Multichannel Perfusion System

for single ion channel and whole-cell solution exchange

● Manual or Programmable PC control with user-friendly GUI interface ● Fast LAFF solenoid valve ● Color-coded polyurethane tubing for easy identification ● Super low dead volume (<100 nL) micromanifold ● Economically priced

inputs from 1/16” ID tubing internal passage ID: 250 µm

PUMPS, MICROINJECTION

mounting rod connector

output: 100 or 250 µm ID quartz/ polymide tubing

14 mm OD internal junction OD: 600 µm

Micromanifold closeup: Fluid-filled passages are shown in magenta.

MPS-2 is a programmable 8-channel perfusion system designed for single channel and whole-cell patch preparations. Offering the best combination of performance and value, the MPS-2 incorporates the same high quality solenoid valves found on similar but much more expensive systems. Unlike other perfusion systems on the market, which often compromise performance to fit every possible application, the MPS-2 is the only perfusion system designed and optimized specifically for single-channel and whole-cell patch perfusion applications.

The system can be controlled manually via membrane switches on the front panel or through a PC. Two different manual control modes are offered. One controls each channel independently and the other mode allows the user to assign a master channel that will keep the system flow when all other channels are switched off. User-friendly graphic timing software is included, and the programmed perfusion sequence can be started by computer, a patch clamp amplifier or other external trigger, or manually by the user

The perfusion fluid flows through specially designed color-coded polyurethane ribbon style tubing. The color-coding MPS-2 Multichannel Perfusion System & Control Software allows the user to easily trace each channel for REPLACEMENT PARTS diagnostic checks or set up and the ribbon style of 502109-15 Color-coded Polyurethane Tubing, 1/16” ID x 8 Channels, 15 ft tubing keeps the system very neat and organized. Unlike 502110 Micromanifold, 100 µm ID tip, 2 pcs/pk PVC based tubing, polyurethane tubing contains no 502125 Micromanifold, 200 µm ID tip, 2 pcs/pk plasticizer, which can cause contamination. The tubing ribbon is designed as an economical disposable item, Specify line voltage and Micromanifold tip OD when ordering. which is often critical when cleanness is needed.

MPS-2 SPECIFICATIONS

CHANNELS VALVE RESPONSE TIME VALVE CONTROL SYRINGE RESERVOIR VOLUME MANIFOLD TIP ID MAXIMUM FLOW RATES (gravity fed) DEAD VOLUME 8 2 ms USB, TTL, external start via software 10 mL 8 to 1 250 micron and 100 micron. 100 µm ID tip, 8 µL/min. at 50 cm 250 µm ID tip, 250-500 µL/min. at 50 cm < 100 nL excluding the single outlet tubing

The most unique feature of the MPS-2 is its perfusion micromanifold. Using the latest microfluidic techniques, the injection molded micromanifold provides the least flow resistance and dead volume of any product on the market. The flow channel inner diameter is approximately 1.0 mm, except for the last 5 mm before the junction point. This design allows a fast flow rate without using a pressured system. The maximum flow rates are 1 and 16 microliter per second for the 50 mm long 100 µm and 250 µm ID tips, respectively. Small channels and a unique design at the merging point further reduce the chance of cross contamination. Dead volume is less than 100 nL.

US: Tel: 941-371-1003 • sales@wpiinc.com

160

UK: Tel: +44 (0)1462 424700 • wpiuk@wpi-europe.com

World Precision Instruments

www.wpiinc.com Germany: Tel: +49 (0)30-6188845 • wpide@wpi-europe.com